We offer the best industrial sheet metal working services.

Please fill out the quote request form below and our expert team will get back to you shortly.

We Offer You Endless Possibilities to Grow

As Expert Sheet Metal Processing Center, we aim to be one of the leading companies in its field. We provide professional service in our sheet metal center to global companies operating in different sectors, especially in Lüleburgaz and Turkey.

Expert Sheet Metal Processing has completed hundreds of industrial projects in all industrial sectors. With a long list of products and never-ending customer support, we are able to guarantee a very high level of satisfaction for consumption.

2022

uzmansacisleme.com

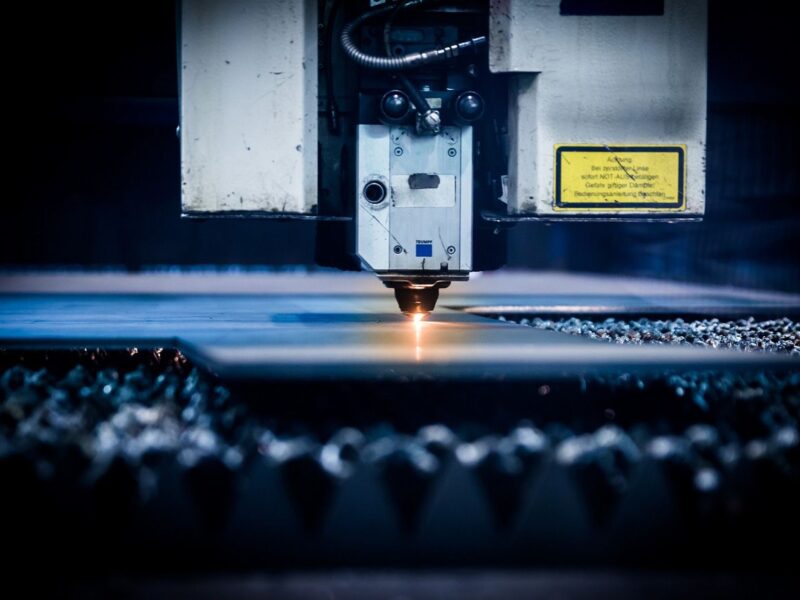

We opened the Expert Sheet Metal Processing Center and started our sheet bending, laser cutting and special design services.

2020

Leader Industrial Cooling

With our Klimexs and Pacific Klima brands, we have become one of the leading costs in the industrial factory cooling sector in the Middle East and Europe.

2012

Expert Tech

As Uzman Teknik, we started our activities in the industrial factory cooling sector in Turkey and Europe.

We make the best of achievement to achieve high standards of results, focused on quality and customer satisfaction.

For you

ExpertSupport

Have an idea, a dream? We can do this.

Call Us: 0 (288) 417 16 86

We have compiled the questions from our business partners and businesses that have just met with the Expert Sheet Metal Processing Center for you.

We process carbon steel, stainless, aluminum, spring steel, copper and brass types smoothly in our 6000 kw Fiber laser polishing machine. Our machine with double input and output table cuts 1500X3000 mm and cutting thicknesses of 25 mm Carbon steel, 20 mm stainless steel, 15 mm aluminum, 8 mm Brass and copper.

The standard delivery time determined by our company is 1-3 working days, your parts are delivered to you by cutting faster in our workbenches according to the work flow.

Our company, which prefers sensitive and smooth cutting quality, may cause scratches on the material surfaces due to undesirable reasons during the production phase. Very small burrs can be seen on the lower edges of aluminum and stainless. For the precision of the cutting surface, our customers can collect the cut parts from the pallet with their own team, check them one by one and consult us at the point where they do not like it.